| Mode | Type of Chamber |

Feed Opening

(mm)

|

Min.Outprt size

(mm)

|

Power (kw) |

Capacity |

| HST100 | S1 super thick |

≤240

|

≥22 | ≤90 | 85-170 |

| S2 coarse thick | ≤200 | ≥19 | 70-130 | ||

| H1 fine | ≤135 | ≥10 | 46-130 | ||

| H2 middle-fine | ≤65 | ≥8 | 35-80 | ||

| H3 super fine | ≤38 | ≥4 | 27-60 | ||

| HST160 | S1 super thick | ≤360 | ≥25 | ≤160 | 120-345 |

| S2 coarse thick | ≤300 | ≥22 | 105-305 | ||

| S3 thick | ≤235 | ≥19 | 90-275 | ||

| H1 fine | ≤185 | ≥13 | 66-210 | ||

| H2 middle-fine | ≤90 | ≥10 | 65-165 | ||

| H3 super fine | ≤50 | ≥6 | 48-105 | ||

| HST250 | S1 super thick | ≤450 | ≥35 | ≤250 | 255-605 |

| S2 super thick | ≤400 | ≥29 | 215-515 | ||

| S3 thick | ≤300 | ≥25 | 190-490 | ||

| H1 fine | ≤215 | ≥16 | 110-395 | ||

| H2 middle-fine | ≤110 | ≥13 | 115-340 | ||

| H3 super fine | ≤70 | ≥8 | 90-255 | ||

| HST315 | S1 super thick | ≤560 | ≥41 | ≤315 | 335-1050 |

| S2 super thick | ≤500 | ≥38 | 305-895 | ||

| H1 fine | ≤275 | ≥16 | 170-665 | ||

| H2 middle-fine | ≤135 | ≥16 | 190-505 | ||

| H3 super fine | ≤65 | ≥13 | 205-320 |

The Limestone Crushing Production Line

The Limestone Crushing Production Line

The limestone crushing production line is an important production element in burn...

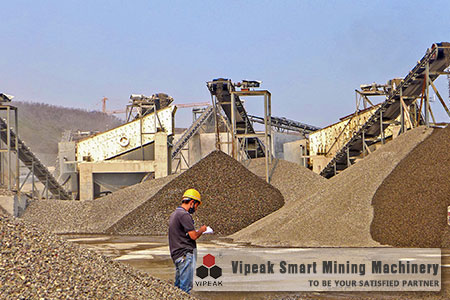

Weathered Sand Making Production Line Site

Weathered Sand Making Production Line Site

Weathered sand has good mechanical properties and has broad prospects in applicat...

Hillstone Crushing Production Line

Hillstone Crushing Production Line

To satisfy the production needs of large quantity and high capacity, Volare sands...

Artificial Granite Sand Making Production Line

Artificial Granite Sand Making Production Line

The choosed crusher machinery in this production plant adopted laminated principl...

We pride ourselves in our commitment and the level of service offered and aim to work closely with customers, to ensure we meet your expectations. Our objective is to keep your business operations running as smoothly as possible on a day-to-day basis.

Using our contact forms you can also send inquiries, give feedback, request information and ask questions.

Copyright © VIPEAK Industry Machinery Co., Ltd. All rights reserved.